Tesla and BMW are looking into using AI-powered humanoid robots in their car manufacturing. BMW has partnered with California startup Figure to deploy “AI Robots” at its Spartanburg, South Carolina plant.

Tesla and BMW are looking into using AI-powered humanoid robots in their car manufacturing. BMW has partnered with California startup Figure to deploy “AI Robots” at its Spartanburg, South Carolina plant.

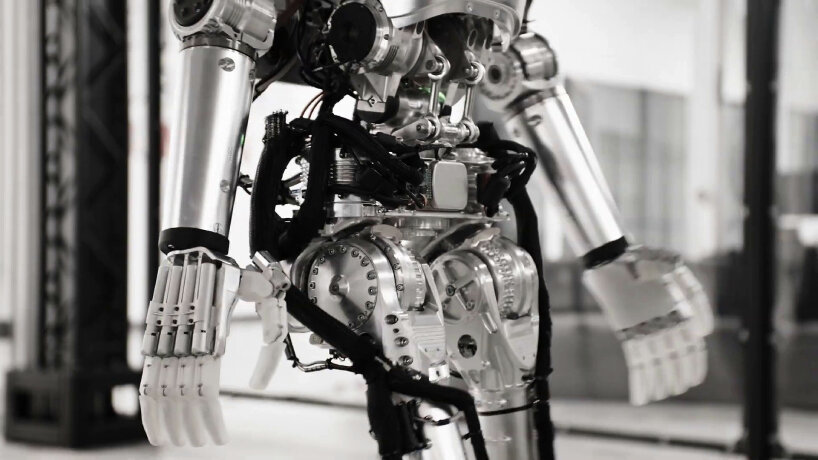

These robots, unlike conventional ones, can handle different tasks, taking on tedious or unsafe jobs previously done by humans.

These robots will be integrated into manufacturing processes, such as the body shop, sheet metal, and warehouse, within the next 12-24 months after undergoing training for specific tasks.

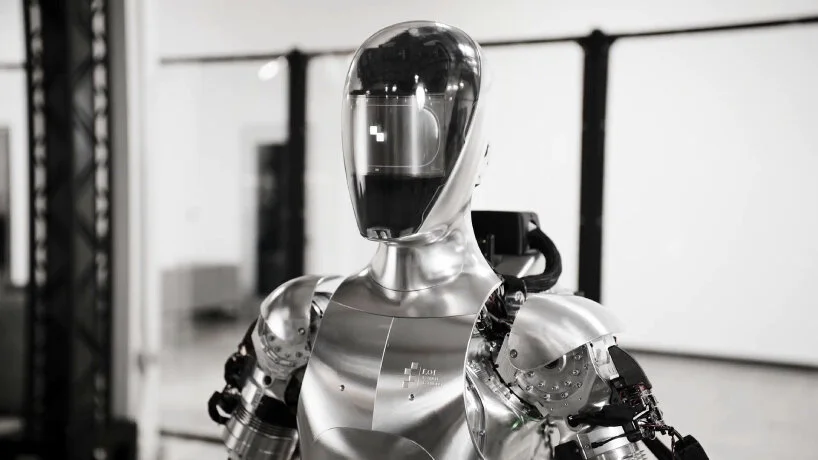

The humanoid robot, Figure 01, from Figure, stands at 5 feet 6 inches, can carry 44 pounds, operates for five hours on a full charge, and walks at a speed of 2.7 miles per hour.

The partnership aims to pinpoint areas in BMW’s manufacturing where these robots can boost productivity, cut costs, and enhance safety.

Tesla is working on a robot called Optimus designed for manual labor in its factories. Elon Musk sees Optimus as a potential personal butler and believes that Tesla’s robotics division could eventually surpass its car business.

The use of humanoid robots in car manufacturing may affect human jobs, especially with the ongoing automation and the transition to electric cars in the automotive industry.

Figure sees its robots as a solution for filling approximately 10 million unfilled jobs in the U.S. that people might not be interested in taking.

Neither company has disclosed the number of Figure’s humanoid robots to be deployed at the facility or the specific tasks they are expected to perform.

Although humanoid robots taking over intricate manufacturing tasks is not imminent, Figure’s robot has shown learning abilities by successfully making coffee with a Keurig machine after observing people for 10 hours.

Just last week Figure 01 learned how to make coffee using an end-to-end AI system

We are excited to be introducing industry leading AI to the automotive sectorpic.twitter.com/DNAZWnaYK3

— Figure (@Figure_robot) January 18, 2024

Starting with a simple task highlights the potential for robots to learn new skills through observation and adaptation.

Honda and Hyundai have been active in developing walking robots, and now efforts to incorporate them into the real world are increasing.

Tesla introduced the second generation of its Optimus robot in December, and Amazon is testing Agility Robotics’ “Digit” robot in its US warehouses.